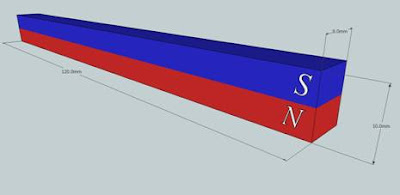

N52 120x8x10mm Big NdFeB Neodymium Block Magnets 20171227

Inquire Big NdFeB Magnets:

I need neodymium block magnets with size of 120mm x 8mm x 10mm with poles on 120mm x 8mm face for ultra low RPM permanent magnet generator.

Please quote your prices for N52 Magnets.

Please also send me catalogue of your common production magnets.

Big Neodymium Permanent Magnets Manufacturer China Rare Earth Magnet Limited:

We can customize this magnet for you.

Please check the below quotation:

Material: NdFeB

Grade: N52

Size: Block Shape, 120x8x10mm

Plating: Black Epoxy

Magnetized or Not: Magnetized

Magnetization Direction: Through 10mm

Ex-works Shenzhen USD***/pc

As for the catalogue, sorry magnets are custom products, we do not have standard price list.

Tags: N52 NdFeB magnets, big neodymium block magnets, permanent magnet, magnet manufacturer, China magnet

2017年12月27日星期三

2017年11月28日星期二

MSDS Material Safety Data Sheet of NdFeB Permanent Magnets 20171124

MSDS Material Safety Data Sheet

of NdFeB Permanent Magnets 20171124

中国稀土永磁有限公司

China Rare Earth Magnet Limited

材料安全资料表

Material Safety Data Sheet

项目/Item

|

材料安全资料表/ Material Safety Data Sheet

|

|

产品与供应商资料

Products and supplier’s data

|

产品名称/Product

|

钕铁硼/Nd-Fe-B

|

产品性能/Specifications

and grade of products

|

规格/Specification:

性能/ Grade:

|

|

供应商名称/Name of

supplier

|

中国稀土永磁有限公司

China Rare Earth Magnet Limited

|

|

供应商地址/Address of

supplier

|

中国深圳南山区深南大道9030号世纪假日广场A座瑞思中心705-707

Room No. 705-707,

Tower A

|

|

供应商电话/Tel. of

supplier

|

86-755-26923096

|

|

邮编/Postal code

|

518053

|

|

成份辨识资料/Ingredients

analysis data

|

Nd:26-33%; Dy-Tb:0-1.5%; Al:0.1-1.0%; B:1.0-1.2%; Fe:63.2-68.5%; Nb:0.3-1.4%

|

|

危害辨识资料/Harm analysis

data

|

健康危害/Harm to health

|

充磁后的产品磁性强,碰撞可能会造成人员手指受伤.

Collision of

magnetized NdFeB magnets

with strong magnetic strength may hurt people’s fingers.

|

环境影响/Influence to

the environment

|

环保产品,经第三方检测机构CTI检测,符合RoHS要求./The environment-oriented products have been

certified by third party CTI and it is compliance with RoHS.

|

|

物理及化学性危害

Physical and chemical harm

|

产品充磁后,磁性强,易损坏电子产品,如手机等/Magnetized products with strong magnetic strength

have detrimental effects on electronic products, such as cell phones

|

|

储运资料/Storage data

|

包装储存要求/Requirements on packing and storage

|

充磁产品隔物包装,进行磁性屏蔽;/Magnetized NdFeB permanent magnets

1)

should be packed with lining and shielding.

2)

储存在通风,干燥,无腐蚀气氛的场所./ Products

should be stored in ventilated, dry and anti-corrosion places

|

搬运要求/Moving

requirements

|

小心轻放,防震,防碰,防雨./Move carefully with shaking-proof,

collision-proof and rain-proof measures

|

|

特殊状况下可能产生的危害反应/Harms

expectable in unusual conditions

|

1) 产品碎裂,缺角;/ Cracks and chips of products

2)产品吸在一起易碰碎或伤人/Magnetization

of magnetized products may collide into pieces or harm people.

|

|

应避免之物质/Materials must be kept away

|

1)

不接触水,防雨/Keep away water and rain;

2) 与铁类物品保持距离/Keep away

iron-made goods

|

|

废弃物处理/Waste treatment

|

废弃物处理办法/Way to treat

waste

|

出售给有资格处理厂家/Sell it to have

handles qualification producers

|

China Rare Earth Magnet Limited Permanent Magnet Manufacturer of Sintered NdFeB Magnets & Magnetic Assembly

2017年10月12日星期四

Radially Ring Magnets Used in Float Kits for Sensors 20171010

Radially Ring Magnets Used in Float Kits for Sensors 20171010

Custom Ring Permanent Magnets Used in Float Kits for Sensors:

We manufacture and remanufacture products such as electronic printers, vacuum pumps, fuel meters, mechanical computers, cash drawers, sensors and related leak detection products.

We interested in manufacturing new float kits for sensors that will be 100% compatible and functionally identical to OEM offerings. These float kits will contain two permanent magnets, one for each float.

I do not know a lot about magnet technology, but here is what I can tell you:

The dimensions are *** OD, *** ID and *** thick. Ring Shape.

I believe they are either molded or bonded based on research I have done.

Each magnet weighs * grams.

I am pretty sure they are radially oriented.

Unfortunately, we do not have the equipment to determine the permanent magnetic material, flux density, coercive field strength etc. What would be the best process for defining the specifications so we could move towards a quote?

Please review the photo and let me know if you are interested in quoting.

Radially Magnetized Permanent Magnet Manufacturer China Rare Earth Magnet Limited:

We can test the magnetic properties if we have your ring magnets.

Is it possible that you can send us 3-5pcs of samples?

Tags: Radially Magnetized Permanent Magnets, Magnet

Custom Ring Permanent Magnets Used in Float Kits for Sensors:

We manufacture and remanufacture products such as electronic printers, vacuum pumps, fuel meters, mechanical computers, cash drawers, sensors and related leak detection products.

We interested in manufacturing new float kits for sensors that will be 100% compatible and functionally identical to OEM offerings. These float kits will contain two permanent magnets, one for each float.

I do not know a lot about magnet technology, but here is what I can tell you:

The dimensions are *** OD, *** ID and *** thick. Ring Shape.

I believe they are either molded or bonded based on research I have done.

Each magnet weighs * grams.

I am pretty sure they are radially oriented.

Unfortunately, we do not have the equipment to determine the permanent magnetic material, flux density, coercive field strength etc. What would be the best process for defining the specifications so we could move towards a quote?

Please review the photo and let me know if you are interested in quoting.

Radially Magnetized Permanent Magnet Manufacturer China Rare Earth Magnet Limited:

We can test the magnetic properties if we have your ring magnets.

Is it possible that you can send us 3-5pcs of samples?

Tags: Radially Magnetized Permanent Magnets, Magnet

2017年9月28日星期四

Construction magnets, Concrete magnets 20170927

Construction magnets, which are also known as architectural precast magnets or concrete blinding magnets, in today's civil engineering construction are indispensable permanent magnetic products. Construction magnet applied to wooden or metal concrete blinding will be a very satisfactory solution. Construction magnet is composed by steel shell and magnet with pressure type handle, steel shell concentrates magnetic curve of the magnet to the bottom so construction magnets have very strong magnetic power.

Usually, people use construction magnets to fix concrete construction blinding, using building permanent magnets are very simple, after fixing building magnets on the concrete blinding, simply pressing down the handle of building magnet, the magnet will tightly attract and catch up the entire concrete construction platform. By using the special magnet crowbar, the handle can be easily raised, and then the construction magnet can be removed.

The holding strength of construction magnetic assembly is between 900 ~ 3100 KGS, construction permanent magnet can also be customized in special size and holding strength.

Tags: construction magnets, concrete magnets, permanent magnet

2017年9月20日星期三

Making permanent magnets by using 3D printer 20170919

Making permanent magnets by using 3D printer 20170919

Presently, the Austrians developed a method of using 3D printers to make permanent magnets. This approach allows using 3D printing technology to print magnets under the condition of precise control of magnetic field. At the same time, this method is especially suitable for magnetic sensors and other equipments.

So far, however, 3D printer is difficult to make true and accurate 3D printed magnets. In order to control the magnetic field of magnets, magnet must have complicated geometrical shape. This shape can be designed by using CAD software, but making actual 3D printing works is still quite difficult. The strength of the magnetic field is not the only factor. Special magnetic field is often needed, and the magnetic field lines arrange in a very specific way, for example, magnetic field in one direction is relatively constant but in another direction changing the intensity of magnetic field. The traditional way to produce this permanent magnet is using injection molding technology. Its technical principle is injecting materials into an inverted mold with similar shape of the object. However, to create the mold is a time-consuming process, and economic cost is too high.

As time goes on, 3D printing has replaced the traditional injection molding process in many applications, and 3D printed magnet is a convincing proof. Using Builder3D printer and a kind of quality polymer material containing magnetic particles can produce 3D printed magnets. The first stage of printing magnet object is to use digital 3D model to specify geometrical shaped print object. As with traditional 3D printing process is to print step layer-by-layer, but 3D printing materials used for printing is composed by about 90% magnetic material and 10% plastic material. However, print shape is just the beginning. Because 3D printing material is made by un-magnetized particles, so the magnetic object itself is not magnetic. Once 3D printing is completed, the printed object needs to be exposed to a strong external magnetic field. The magnetic field will convert 3D printing object to permanent magnets. This approach allows dealing with all kinds of magnetic materials, such as particularly strong NdFeB magnets. Now, using computers to create magnet design can be realized quickly and accurately in size from cm to dm., and the accuracy is 1 mm. Rapid and cost-effective new magnet 3D printing offers scientists the possibility of studying new products, including using different materials within a single magnet form a smooth transition between strong and weak magnet.

Tags: Making permanent magnets by using 3D printer, NdFeB magnets, magnetic materials

Presently, the Austrians developed a method of using 3D printers to make permanent magnets. This approach allows using 3D printing technology to print magnets under the condition of precise control of magnetic field. At the same time, this method is especially suitable for magnetic sensors and other equipments.

So far, however, 3D printer is difficult to make true and accurate 3D printed magnets. In order to control the magnetic field of magnets, magnet must have complicated geometrical shape. This shape can be designed by using CAD software, but making actual 3D printing works is still quite difficult. The strength of the magnetic field is not the only factor. Special magnetic field is often needed, and the magnetic field lines arrange in a very specific way, for example, magnetic field in one direction is relatively constant but in another direction changing the intensity of magnetic field. The traditional way to produce this permanent magnet is using injection molding technology. Its technical principle is injecting materials into an inverted mold with similar shape of the object. However, to create the mold is a time-consuming process, and economic cost is too high.

As time goes on, 3D printing has replaced the traditional injection molding process in many applications, and 3D printed magnet is a convincing proof. Using Builder3D printer and a kind of quality polymer material containing magnetic particles can produce 3D printed magnets. The first stage of printing magnet object is to use digital 3D model to specify geometrical shaped print object. As with traditional 3D printing process is to print step layer-by-layer, but 3D printing materials used for printing is composed by about 90% magnetic material and 10% plastic material. However, print shape is just the beginning. Because 3D printing material is made by un-magnetized particles, so the magnetic object itself is not magnetic. Once 3D printing is completed, the printed object needs to be exposed to a strong external magnetic field. The magnetic field will convert 3D printing object to permanent magnets. This approach allows dealing with all kinds of magnetic materials, such as particularly strong NdFeB magnets. Now, using computers to create magnet design can be realized quickly and accurately in size from cm to dm., and the accuracy is 1 mm. Rapid and cost-effective new magnet 3D printing offers scientists the possibility of studying new products, including using different materials within a single magnet form a smooth transition between strong and weak magnet.

Tags: Making permanent magnets by using 3D printer, NdFeB magnets, magnetic materials

2017年9月5日星期二

Ferrite and Neodymium Permanent Magnets for Inverter Air-conditioner 20170905

Ferrite and Neodymium Permanent Magnets for Inverter Air-conditioner 20170905

Inverter Air-conditioner-------- EPS and micro motors demanding more NdFeB neodymium magnets

Magnets that mainly used in compressors of inverter air-conditioners can be classified into ferrite permanent magnets and high-performance NdFeB magnets. Ferrite magnets are mostly used in mid-low end products, while neodymium magnets are commonly used in high-end inverter air-conditioners. Due to policy support of energy conservation and technology upgrading, ferrite magnets will gradually replaced with high-performance of NdFeB in area of inverter air-conditioners.

In 2016, 16049 air-conditioners were produced in 2016, with year-on-year growth of 2.55%, among which there were 3963 inverter ones, with year-on-year growth of 2.7%. Penetration rate of high-end inverter air-conditioners reached 40%. Each high-end air-conditioner consumes 0.28kg of high-performance neodymium rare earth permanent magnets. According to estimation, in 2016, there was 4438 tons of NdFeB magnets applied in inverter air-conditioners. Suppose that in 2017 and 2018, growth rate of domestic output of air-conditioners is 3% and penetration rate of high-end inverter air-conditioners is 2%, then in 2017 and 2018, consumption of neodymium permanent magnet will be 4800 tons and 5179 tons, with growth rate of 8.15% and 7.9%.

China Rare Earth Magnet Limited manufactures magnets for air-conditioner, if you have such demand, welcome to sending enquiry with drawing or actual sample for testing!

Tags: magnets for inverter air-conditioner, permanent magnet, ferrite magnets, neodymium magnets China magnet, magnet manufacturer

Inverter Air-conditioner-------- EPS and micro motors demanding more NdFeB neodymium magnets

Magnets that mainly used in compressors of inverter air-conditioners can be classified into ferrite permanent magnets and high-performance NdFeB magnets. Ferrite magnets are mostly used in mid-low end products, while neodymium magnets are commonly used in high-end inverter air-conditioners. Due to policy support of energy conservation and technology upgrading, ferrite magnets will gradually replaced with high-performance of NdFeB in area of inverter air-conditioners.

In 2016, 16049 air-conditioners were produced in 2016, with year-on-year growth of 2.55%, among which there were 3963 inverter ones, with year-on-year growth of 2.7%. Penetration rate of high-end inverter air-conditioners reached 40%. Each high-end air-conditioner consumes 0.28kg of high-performance neodymium rare earth permanent magnets. According to estimation, in 2016, there was 4438 tons of NdFeB magnets applied in inverter air-conditioners. Suppose that in 2017 and 2018, growth rate of domestic output of air-conditioners is 3% and penetration rate of high-end inverter air-conditioners is 2%, then in 2017 and 2018, consumption of neodymium permanent magnet will be 4800 tons and 5179 tons, with growth rate of 8.15% and 7.9%.

China Rare Earth Magnet Limited manufactures magnets for air-conditioner, if you have such demand, welcome to sending enquiry with drawing or actual sample for testing!

Tags: magnets for inverter air-conditioner, permanent magnet, ferrite magnets, neodymium magnets China magnet, magnet manufacturer

2017年8月29日星期二

Application of high performance NdFeB magnets in automobile EPS field 20170829

In traditional vehicles, NdFeB permanent magnets are mainly used for EPS steering system. Each EPS system need 0.15 kg finished NdFeB magnets, amount to 0.25 kg blank. To calculate with global production of 9498 cars in 2016 and 50% of the EPS system permeability, NdFeB blank consumption in global EPS systems is at least 11800 tons. Automobile steering system plays a key role on vehicle handling stability and safety. HPS steering system is drived by engine and hydraulic power. This system is mature in technology, but has too many parts, big in volume and heavy in weight. EPS steering system is completely drived by electronic controlled permanent magnet servo motor, which has multiple advantages like compact structure, high efficient and reliable, energy conservation, environmental protection and high safety. In the future, EPS will gradually replace HPS system has become the consensus of the market.

With the improvement of vehicle stability and safety requirements in high-end models, the permeability of EPS in global traditional cars gradually increased from 9% in 2010 to the current 50% or so. Permeability of EPS system in our domestic cars is 40-45% at present, while European and American market share is over 80%, and that of Japan even reached 90%. Therefore, there is still great increase space in the domestic EPS market. According to the following assumptions: 1) in 2017 and 2018 domestic automobile production year-on-year growth of 5% , the global car production year-on-year growth of 4%; 2) domestic EPS permeability increased by 4.5% per year, the global penetration of EPS increased by 3% per year, the expected usage of NdFeB rare earth permanent magnets in domestic EPS system with summary of year-on-year growth will be 15% or so in 2017 and 2018 , and the usage of NdFeB in global EPS system year-on-year growth is 10% or so.

Tags: NdFeB magnets, Automobile magnets, EPS magnets, permanent magnets, magnet manufacturer, China magnet

订阅:

博文 (Atom)