Making permanent magnets by using 3D printer 20170919

Presently, the Austrians developed a method of using 3D printers to make

permanent magnets. This approach allows using 3D printing technology to print magnets under the condition of precise control of magnetic field. At the same time, this method is especially suitable for magnetic sensors and other equipments.

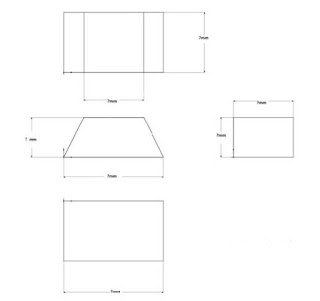

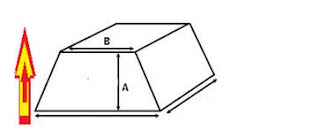

So far, however, 3D printer is difficult to make true and accurate 3D printed magnets. In order to control the magnetic field of magnets, magnet must have complicated geometrical shape. This shape can be designed by using CAD software, but making actual 3D printing works is still quite difficult. The strength of the magnetic field is not the only factor. Special magnetic field is often needed, and the magnetic field lines arrange in a very specific way, for example, magnetic field in one direction is relatively constant but in another direction changing the intensity of magnetic field. The traditional way to produce this

permanent magnet is using injection molding technology. Its technical principle is injecting materials into an inverted mold with similar shape of the object. However, to create the mold is a time-consuming process, and economic cost is too high.

As time goes on, 3D printing has replaced the traditional injection molding process in many applications, and 3D printed magnet is a convincing proof. Using Builder3D printer and a kind of quality polymer material containing magnetic particles can produce 3D printed magnets. The first stage of printing magnet object is to use digital 3D model to specify geometrical shaped print object. As with traditional 3D printing process is to print step layer-by-layer, but 3D printing materials used for printing is composed by about 90%

magnetic material and 10% plastic material. However, print shape is just the beginning. Because 3D printing material is made by un-magnetized particles, so the magnetic object itself is not magnetic. Once 3D printing is completed, the printed object needs to be exposed to a strong external magnetic field. The magnetic field will convert 3D printing object to permanent magnets. This approach allows dealing with all kinds of

magnetic materials, such as particularly strong

NdFeB magnets. Now, using computers to create magnet design can be realized quickly and accurately in size from cm to dm., and the accuracy is 1 mm. Rapid and cost-effective new magnet 3D printing offers scientists the possibility of studying new products, including using different materials within a single magnet form a smooth transition between strong and

weak magnet.

Tags: Making permanent magnets by using 3D printer, NdFeB magnets, magnetic materials