Are you wondering what one-side magnet is? Here to introduce the one-side magnets.

The Introduction of One-side Magnets

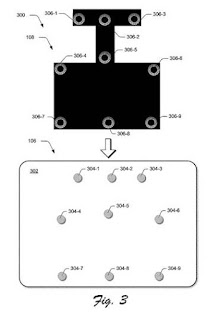

Permanent Magnets have two poles, but in some specific working positions a single-pole magnet is needed. So we need to encase one side of magnet by metal plates, in order to shield the magnetism of that side. And strengthen the magnetism of the other side through the refraction of metal plates. These magnets are collectively known as one-sided magnets. But actually, the real one-sided magnets don’t exist.

The Material of One-side Magnets

The material used for one-side magnets is neodymium rare earth magnets. Most of the one side magnets are disc shapes.

The Application of One-side Permanent Magnet

1、One-side magnets are widely used in presswork industry. There exist one-side magnets in gift boxes, phone boxes, tobacco and wine boxes, MP3 boxes and moon cake boxes, etc.

2、They are also widely used in leather industry, such as bags, suitcases, briefcases, traveling bags, cell-phone cases, wallets and so on.

3、In Stationery industries, one side magnets are used in notebooks, white boards, folders, and magnetic name badges.

The Purchasing Considerations of One-side Magnets.

The manufacture of one-side magnets is to artificially put the neodymium magnets into the metal plates. So it will take a pretty long time to produce. Customers who want to purchase should place the order in advance.

There are many specifications of one-side magnets. China Rare Earth Magnet limited can customize the magnets according to your requirements. Please send e-mail to us if you have any demand for magnets.

Tags: permanent magnet

The Introduction of One-side Magnets

Permanent Magnets have two poles, but in some specific working positions a single-pole magnet is needed. So we need to encase one side of magnet by metal plates, in order to shield the magnetism of that side. And strengthen the magnetism of the other side through the refraction of metal plates. These magnets are collectively known as one-sided magnets. But actually, the real one-sided magnets don’t exist.

The Material of One-side Magnets

The material used for one-side magnets is neodymium rare earth magnets. Most of the one side magnets are disc shapes.

The Application of One-side Permanent Magnet

1、One-side magnets are widely used in presswork industry. There exist one-side magnets in gift boxes, phone boxes, tobacco and wine boxes, MP3 boxes and moon cake boxes, etc.

2、They are also widely used in leather industry, such as bags, suitcases, briefcases, traveling bags, cell-phone cases, wallets and so on.

3、In Stationery industries, one side magnets are used in notebooks, white boards, folders, and magnetic name badges.

The Purchasing Considerations of One-side Magnets.

The manufacture of one-side magnets is to artificially put the neodymium magnets into the metal plates. So it will take a pretty long time to produce. Customers who want to purchase should place the order in advance.

There are many specifications of one-side magnets. China Rare Earth Magnet limited can customize the magnets according to your requirements. Please send e-mail to us if you have any demand for magnets.

Tags: permanent magnet